Hot stamping printing has always been loved by people because of its unique effect. The T agency customization platform is going to talk about the process flow of bronzing printing today.

Procedure.

Firstly beat the bronzing paste up and down evenly, and it can be printed after the air bubbles are cleared.

In the first pass, the three knives are applied with a little force, so that the bronzing paste can fully combine with the fabric and dry slightly.

The second printing is three knives, the normal printing pressure, and the third printing should be carried out after a little drying.

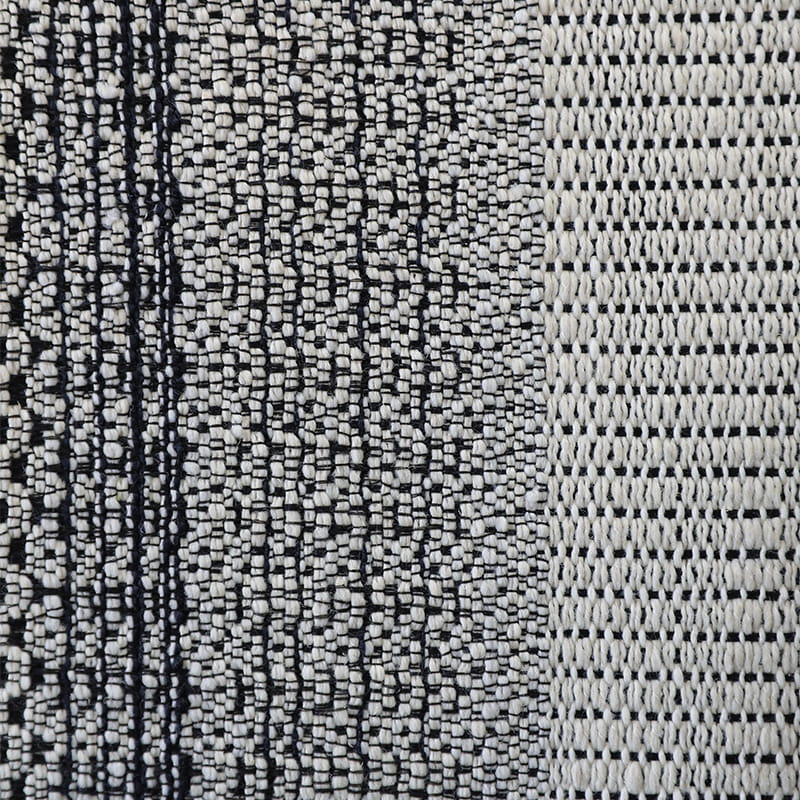

Let the bronzing paste fill the cloth pattern to achieve a flat and smooth state, which is conducive to the complete combination with Jinbo. After three times of drying, it can be hot pressed, and the

Adjust the temperature of the ironing press to 120°C-130°C for 15 seconds, press the pressure of the ironing machine at 3 kg, and then cool it down to tear off the gold foil.

After 24 hours, it can be washed with water. If 1% cross-linking agent PC100 is added, the washing fastness will be better.

Haining Shenglong Textile Technology Co., Ltd. is a professional bronzing and printing fabric manufacturers. If you need it, you can click the official website to contact us. We are willing to answer you for more information.

English

English 简体中文

简体中文